Oregon State University Seafood Research and Education Center

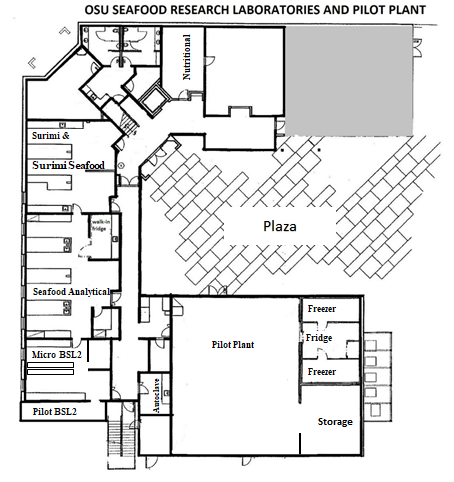

The Oregon State University Seafood Research and Education Center is an Agriculture Experiment station that was established in Astoria, OR in 1940 and has served the seafood industry for over fifty years. Since 1989 it has been part of the Coastal Oregon Marine Experiment Station at OSU. The new Laboratory facility was completed in 1997 and is a 21,000 sq. ft. building of which 15,000 sq. ft. consist of laboratories, pilot plant and office space dedicated to seafood research. The Seafood Laboratory has state-of-the art laboratory facilities including a food engineering lab, a seafood biochemistry lab and a biosafety level 2 microbiology lab, a tissue culture lab and pilot processing area. There is a 3,500 sq. ft. pilot plant with several scale-up equipment and operational capabilities. The pilot plant includes one walk-in refrigerator space and two additional walk-in spaces that can be controlled for either frozen storage or refrigerated storage.

The Seafood Analytical Lab contains equipment to study the chemistry and biochemistry of seafood products. It contains equipment for nutritional and quality evaluation of seafood products. Equipment includes Kjeldahl protein analyzer, fat extraction, muffle furnace, moisture ovens (including convection), incubators, Gas Chromatographs, High Pressure Liquid Chromatographs, UV-VIS and Fluorescence Spectrophotometers, pH meters, water activity. In addition the lab contains a walk-in cold room electrophoresis equipment, Gel-DOC and Real-time PCR.

The Surimi and Surimi Seafood Lab contains equipment to both make and study the rheological properties of protein gels. It contains sausage making equipment, jacketed Hobart mixers, sausage stuffer, ohmic heater and incubators. It also contains gel testing equipment that includes torsion and Sintech texture monitors, dynamic rheometer, texture profile analyzer, and a differential scanning calorimeter.

If you are interested in working in this area or using this equipment contact Dr. Jae Park.

The seafood microbiology laboratory is a 580 sf Biosafety Level 2 (BSL2) facility. This means research can be conducted using common foodborne pathogens. This facility has a laminar hood and all the equipment needed to culture and ID microorganisms. The laboratory contains a 4 ft laminar hood, two upright incubators, upright -80 freezer, table top incubators, ultracentrifuge, microcentrifuge, sonicator, Protean 2II gel electrophoresis units, themocyclers and nanophotometer.

The Seafood Microbiology Lab also has a 160 sf BSL2 pilot facility space adjacent to the laboratory to support pilot level research with foodborne pathogens. This space has been used to conduct depuration experiments with oysters and crustaceans. As a result, it contains two lab scale depuration systems with each system containing two 100 L reservoirs. It also contains a 600 L pilot scale depuration system.

Across the hall from the microbiology lab is the autoclave room.

Adjacent to the microbiology lab is the Seafood Analytical Lab which also contains three preparative centrifuges, a table micro centrifuge and Bio-Rad CFX96 Real-Time PCR Detection System for multiplex PCR.

Marine Bioactive Compounds and Human Health

Kwon Lab (Nutritional Pharmacology Lab) studies biological effects and functions of natural molecules derived from diverse marine species at cellular and physiological levels. Research interest includes identifying marine-derived bioactive compounds with metabolic regulatory effect, anti-cancer effect, and anti-microbial effect. Kwon Lab's research effort supports developing useful biomedical applications for human health promotion and disease prevention and uncovering potential health value of seafood materials and underutilized aquatic resources to promote effective utilization of the harvested resources.

Kwon Lab's research is conducted at the laboratories at OSU Seafood Research & Education Center and Linus Pauling Science Center.

The Seafood Lab Pilot Plant is approximately 3,500 sq. ft. with a loading dock. It has approximately 550 sq. ft. of cold storage. One freezer of 160 sq. ft., one flexible freezer/refrigerator storage space of 160 sq. ft., and about 200 sq ft refrigerated storage space. The facility is designed for flexible usage with excess power, water, and steam access. It contains a three compartment commercial sink with both stainless steel and poly top mobile cutting tables. Equipment currently housed include an Enviro-Pak CVU-200E Smoker (capacity ~ 50 lbs raw material), Wolf-Tec Imax 350 Injector, Dixie Vertical Retort (capacity ~50 lbs raw material) with flexible retort holder and Multivac flexible retort sealer, Reiser Vacuum Sealer, and 2L Jacketed Engineered Pressure System High Hydrostatic Press (up to 600 MPa).

The pilot facility is used to support various research projects by faculty. It is also used for service fee projects including product development and shelf-life studies (with or without retail lights).